Rotomolding technology is also called rotational molding technology that put the plastic powder into the mold, so that the powder in the mold around the two vertical axes heat and rotate. Due to the rotation, powder changes unceasingly, and rubbers each other, the drag of its mold surface, which make the powder continue to move to the mold’s upper arm. It is not until the movement force enough to overcome the gravity that power bears that the powder is able to across the powder pool to reach the opposite mold wall, and the powder rotates the mold 360.

After repeated heated rotation, the powder will be melted and evenly adhered to the inner wall of the mold and melt into one. After reaching the required thickness, it should be cooled and shaped and taken out the hollow products from the mold.

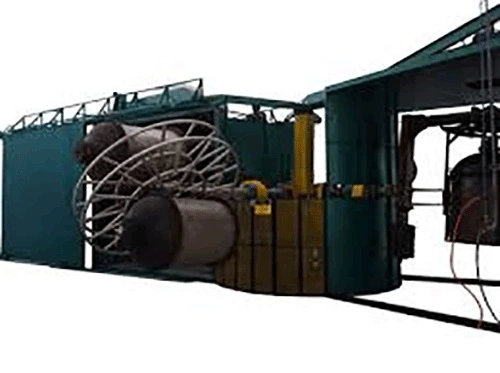

Compared with the traditional hollow plastic molding methods, the rotational molding equipment has incomparable advantages in equipmentinvestment cost, manufacturing cycle, and technique flexibility. It has become the most ideal, economical and effective method for small batch production of medium, large and super large closed or semi closed seamless hollow container.

Rotational molding process has outstanding characteristics. Rotational technique equipment costs less in investment, and the mold processing cost is low, the comprehensive cost of producing the same volume of product is low .The technique saves raw materials, almost 100% of the material can be converted into products. There is no runner and gate inside of the mold, so this technique does not produce waste. What’s more, the wall thickness of the product is evenly, and the chamfer is slightly thicken, which give full play to the performance of the material.

Rotomolding technique is suitable for producing large and super large products, and especially for molding all kinds of complex shaped hollow parts. In the rotational molding process, the material is gradually coated on the surface of the mold, and has a strong ability to replicate fine structure such as die cavity surface patterns. Meanwhile, due to the die in the forming process suffers no pressure effect, the precision casting methods can be adopted directly to produce a variety of fine and complex mold to forming, such as toys, animal models and resin based composite products.

Rotomold is suitable for the production of resin based composite multilayer material. Rotational molding multi-layer products, it only need pouring the resin through reasonable matching, with different melting point into a mold. During the molding process, the material with low melting temperature will melt first and adhered to the cavity wall to formed parts of the outer layer. After then, the material with higher melting temperature melt, it will be attached on the outer material forming the inner layer, or pouring the outer resin into mold, rotomolding into the outer layer of the workpiece, and then join the inner resin, forming the parts of multi-layer rotary molding.

The product made by rotational molding has no stress, almost no optional orientation or residual strain; It also does not exists sag, deformation and cracking problems.

Rotomold is suitable for the production of many varieties, small batch resin based composite material products, and it is easy to transform composite material’s color. In addition, the process has the advantages of simple forming, strong adaptability and convenient replacement of the mold. The equipment, with simple structure, is convenient and effective to manufacture, besides, its price is low, and therefore the product is very favorable for transformation. In the production process, a rotational molding machine can mold the very different products in size and shape.

Rotational molding also has some disadvantages, such as larger consumption, longer molding cycle, poor molding product size accuracy, large labor intensity, and so on.